In the world of industry, testing procedures are vital for ensuring product quality, safety, and compliance with regulations. Whether it’s testing raw materials, components, or finished products, the accuracy and reliability of testing methods can make or break a company’s reputation. In this blog post, we’ll delve into the top facts every company should know about industrial testing procedures.

Types of Industrial Testing

Industrial testing encompasses a wide range of methods and techniques tailored to specific industries and applications. Some common types of industrial testing include:

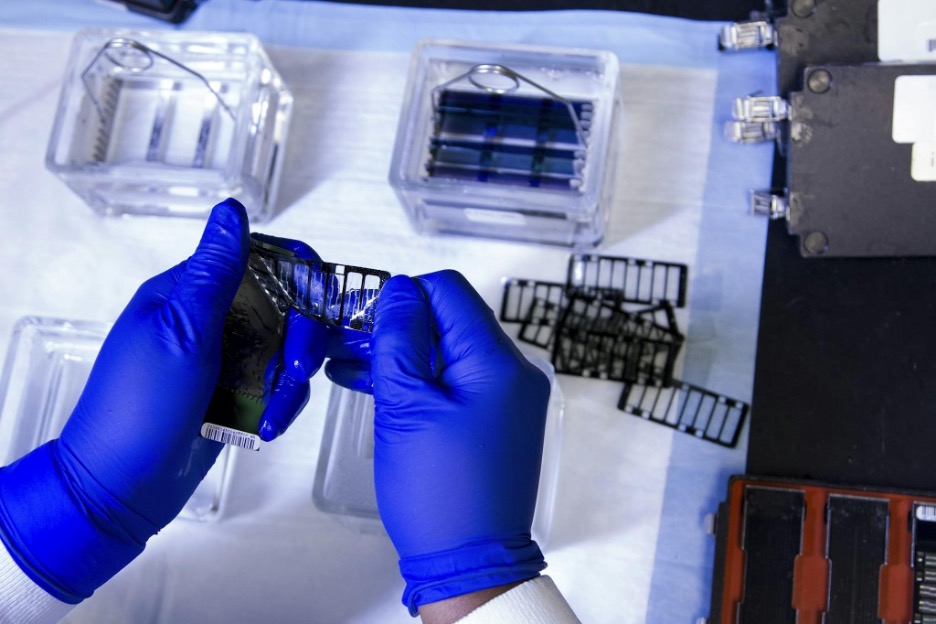

Non-Destructive Testing (NDT): Non-Destructive Testing (NDT) encompasses a range of techniques designed to inspect materials and components without causing any damage. This non-destructive testing for businesses includes using X-rays to penetrate materials and reveal internal structures, ultrasonic testing to detect flaws or anomalies through sound waves, and magnetic particle testing to identify surface cracks or discontinuities. By employing NDT techniques, companies can ensure the quality, safety, and reliability of their products without compromising their structural integrity or performance.

Material Testing: Evaluating the properties of raw materials such as metals, plastics, and composites to ensure they meet quality standards and performance requirements.

Product Testing: Testing finished products to assess their functionality, durability, safety, and compliance with regulatory standards.

Environmental Testing: Assessing the impact of products or processes on the environment, including tests for emissions, pollutants, and waste management.

Quality Control Testing: Monitoring production processes to identify defects, deviations, and quality issues before products reach consumers.

Each type of testing serves a unique purpose and contributes to overall quality assurance and risk mitigation within an industry.

Importance of Testing in Industry

Testing plays a crucial role in various industries, including manufacturing, pharmaceuticals, automotive, aerospace, and more. It helps companies ensure that their products meet required standards, perform as expected, and pose no risks to consumers or the environment. Without proper testing, companies may face costly recalls, legal issues, and damage to their brand reputation.

Regulatory Compliance and Standards

Compliance with regulatory standards is a critical aspect of industrial testing. Different industries have specific regulations and standards that companies must adhere to. For example:

ISO Standards: The International Organization for Standardization (ISO) sets global standards for quality management, environmental practices, and product safety.

FDA Regulations: The Food and Drug Administration (FDA) in the United States regulates testing and approval processes for pharmaceuticals, medical devices, and food products.

ASTM Standards: The American Society for Testing and Materials (ASTM) develops and publishes standards for materials, products, systems, and services.

Failure to comply with these standards can result in legal consequences, product recalls, and damage to a company’s reputation. Therefore, companies must stay updated with relevant regulations and ensure their testing procedures meet required standards.

Emerging Technologies in Industrial Testing

The field of industrial testing is constantly evolving, driven by technological advancements and innovation. Some notable trends and technologies in industrial testing include:

Automation and Robotics: Automated testing systems improve efficiency, reduce human error, and enable faster processing of test samples.

Big Data Analytics: Analyzing large datasets generated from testing processes helps identify trends, predict failures, and optimize performance.

Internet of Things (IoT): Connected sensors and devices enable real-time monitoring of equipment, processes, and environmental conditions.

Artificial Intelligence (AI): AI algorithms enhance data analysis, pattern recognition, and decision-making in testing and quality control.

3D Printing and Additive Manufacturing: Testing methods are evolving to accommodate the unique properties and requirements of 3D-printed materials and components.

By embracing these technologies, companies can improve the accuracy, efficiency, and scalability of their testing procedures, leading to better overall outcomes.

Industrial testing procedures are integral to ensuring product quality, safety, regulatory compliance, and customer satisfaction. Companies that prioritize accurate, reliable, and innovative testing methods stand to gain a competitive advantage and build a reputation for excellence in their respective industries. By staying informed about the latest trends, regulatory requirements, and technological advancements in industrial testing, companies can navigate challenges effectively and drive continuous improvement in their testing processes.